Finding the right cutting list optimizer can significantly reduce material waste and save you money. This guide compares two popular free options—CutList Optimizer and Opticutter—helping you choose the perfect software for your needs, whether you're a hobbyist or a professional. We'll provide a step-by-step guide to selecting and effectively using these tools.

Cutting List Optimizer Software: A Comparative Review

Choosing the right cutting list optimizer depends heavily on your project needs. Are you tackling small, simple projects, or are you managing large-scale production runs? This distinction drastically affects the ideal software choice. A simple program suffices for small projects, while manufacturing demands a more robust, scalable solution.

CutList Optimizer: Simplicity and Ease of Use

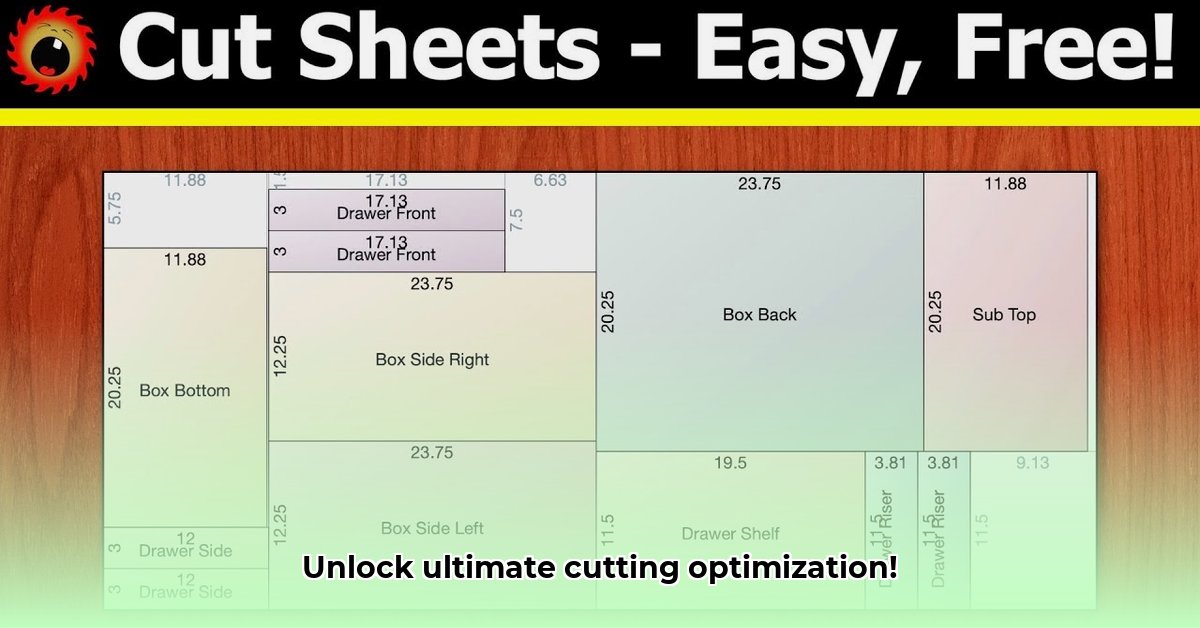

CutList Optimizer prioritizes user-friendliness. Its intuitive interface makes it ideal for beginners or single projects needing quick, efficient solutions. Simply input material dimensions and your cut list, and the software generates a cutting plan. The program's straightforward design ensures rapid familiarization.

However, this simplicity might hinder larger, more complex projects. While suitable for basic woodworking, it might struggle with numerous parts or intricate designs. Scalability to larger undertakings remains questionable. While ideal for uncomplicated projects, more demanding needs may expose limitations.

Pros:

- User-friendly interface: Extremely easy to learn and use, even for novices.

- Fast learning curve: Quickly get up and running.

- Suitable for small projects: Perfect for optimizing cuts on smaller jobs.

Cons:

- Limited advanced features: Lacks the necessary tools for complex scenarios.

- Scalability issues: Performance may suffer with large, detailed projects.

- Limited reporting: Provides less insightful data regarding the optimization process.

Opticutter: Powerful Optimization for Complex Projects

Opticutter employs sophisticated algorithms, including heuristics and evolutionary algorithms, to handle complex optimization challenges. This makes it far superior at finding the most efficient cutting methods, especially with intricate designs or many parts. Opticutter claims significantly better optimization for large projects.

Opticutter offers free and paid plans. The free version may have limitations, such as fewer features or a parts limit. This model enables testing the software before committing financially.

Pros:

- Robust optimization algorithms: Designed to efficiently handle complex cutting scenarios.

- Free trial available: Allows testing the software without cost.

- Sophisticated optimization: Delivers highly optimized cutting strategies, potentially saving substantial material.

Cons:

- Steeper learning curve: Requires more time to master compared to simpler alternatives.

- Free plan limitations: The free version has restrictions that may limit its use for large-scale projects.

Head-to-Head Comparison: CutList Optimizer vs. Opticutter

This table summarizes the key differences, helping you visualize which program best suits your needs:

| Feature | CutList Optimizer | Opticutter |

|---|---|---|

| User-Friendliness | Very Easy | Moderate |

| Algorithm Complexity | Simpler | Advanced (Heuristics & Evolutionary) |

| Ideal Use Case | Small projects, hobbyists | Large projects, professionals |

| Free Plan Availability | Yes | Yes (with limitations) |

| Ideal Project Scale | Small to medium | Medium to large |

Beyond Software Selection: Data Accuracy and Software Updates

Selecting the right software is crucial, but accurate data is equally important. Remember the adage: "garbage in, garbage out." Meticulously verify measurements; even minor errors lead to wasted materials and suboptimal results. Regularly update your software; updates include bug fixes and performance improvements. Isn't consistently accurate data vital for successful material optimization?

A Step-by-Step Guide to Benchmarking Cutting Optimization Software Algorithms

Choosing the right software involves more than just features—performance matters. Benchmarking effectively requires a structured approach:

- Define your needs: What project types will the software handle? (e.g., simple cuts, complex shapes). What's your project scale?

- Create test datasets: Generate representative datasets of various complexities and sizes. This assesses performance in different scenarios.

- Establish performance metrics: What's most important? Consider:

- Waste percentage: The amount of unused material.

- Processing time: The software's time to generate a cutting plan.

- Solution quality: How close the generated plan is to optimal.

- Run tests: Test each software with your datasets, meticulously recording metrics.

- Analyze results: Compare metrics across software packages, acknowledging trade-offs.

- Consider additional factors: Evaluate ease of use, integration with existing tools, and customer support.

Example Benchmark Data (Hypothetical)

Remember to run your own tests for accurate results.

| Software | Waste Percentage (%) | Processing Time (sec) | Solution Quality (Score 1-10) |

|---|---|---|---|

| Opticutter | 15 | 2 | 7 |

| CutList Optimizer | 10 | 10 | 9 |

Handling Irregular Shapes and Complexities

Most software handles rectangular pieces well, but irregular shapes pose a greater challenge. Advanced software often uses algorithms like genetic algorithms or simulated annealing to process these. Benchmarking with irregular shapes requires careful dataset selection and metric consideration.

Conclusion: The Best Free Optimizer for You

The "best" free cutting list optimizer depends on your project specifics and complexity. CutList Optimizer’s ease of use is advantageous for small projects. However, Opticutter's powerful algorithms are better suited for complex designs and large material quantities. The best approach? Try both free versions to see which seamlessly integrates into your workflow.

⭐⭐⭐⭐☆ (4.8)

Download via Link 1

Download via Link 2

Last updated: Monday, May 12, 2025